What really killed vehicle manufacturing in Australia?

The death knell for Australia’s vehicle manufacturing industry was not because of high labour costs, writes Andreas Bimba in this guest article, but the free-trade agreements that acted to the detriment of the local industry. And who signed them? You won’t be too surprised to learn who.

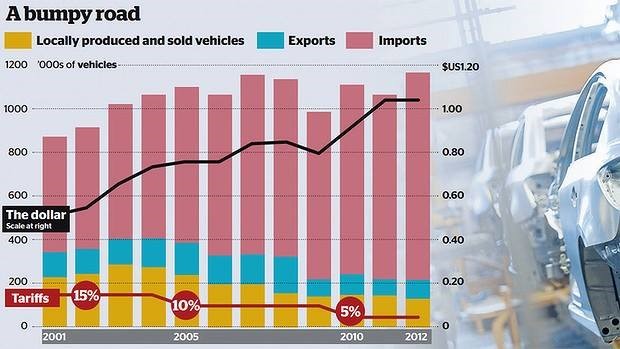

Toyota, Holden and Ford did not decide to cease local automotive manufacturing because of high labour costs (this is nothing new), nor from a lack of direct financial support (this has been fairly constant but small), although both of these factors added to the pressure. Primarily, it was because of inadequate trade protection of the Australian new car market, the historically high Australian dollar, and finally, extreme hostility shown by the current Federal Government and the Productivity Commission in regard to dealing effectively with the urgent concerns of the industry.

It is quite obvious really, but as we have come to expect, the truth of the matter has largely been ignored by our superficial national media. The main headwind of the many facing Toyota Australia’s local manufacturing operations, and also those of Holden and Ford, is the one-sided Free Trade Agreements (FTAs) signed by our Federal Governments and the almost complete lack of tariff protection.

These FTAs conform to the neo-liberal philosophy of global free trade that is currently in favour with the Coalition Government, the Federal Government’s advisory bodies such as the incompetent Productivity Commission, and also the Australian Labor party.

The Australia Thailand Free Trade Agreement (TAFTA) came into force on the 1st of January 2005 and was implemented by Prime Minister John Howard.

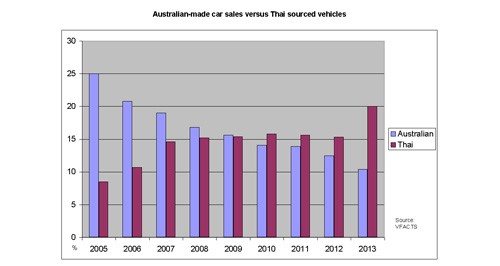

This agreement has allowed Thailand’s subsidised vehicles into Australia without restriction but has not prevented Thailand imposing secondary restrictions that have totally prevented Australian vehicles from being sold into the Thai market. Australia’s three top selling vehicles in 2013; the Toyota Corolla (43,498 units), the Mazda 3 (42,082 units) and the Toyota HiLux (39,931 units) all came from Thailand. By comparison, for 2013 the Australian made Holden Commodore sold 27,766 units locally and the Toyota Camry sold 24,860 units locally. I have not included Australian exports in these figures.

Over the preceding eight years not one Australian government has addressed the inequities of this vehicle trade imbalance and have stood back and ignored the inevitable consequences. Perhaps the Australian automotive manufacturers have also not tried diligently enough to address this trade imbalance as most of the vehicles being imported were made by subsidiaries of the parent companies.

This chart from GoAuto clearly shows what has been happening from 2005 to 2013. For the Australian new vehicle market it shows total Australian made vehicle sales (exports excluded) and total Thailand made vehicle sales.

The Australia Korea Free Trade Agreement (FTA) came into force on the 5th of December 2013 and was implemented by the Abbott Government. Korea has an almost totally protected car market and provides substantial subsidies to its manufacturers. It is also a much larger and more advanced automotive manufacturer than Thailand.

On the 11th December 2013 General Motors Holden announced the planned closure of its Australian manufacturing operations from the end of 2017.

On the 10th February 2014 Toyota Australia also announced the planned closure of its Australian manufacturing operations from the end of 2017.

It looks fairly clear to me that Holden and Toyota Australia concluded that the Australia Korea FTA was the last nail in the coffin and that there was no longer any point in baring their trading losses in the hope that the national industrial policy environment would improve.

The fact that Holden and Toyota Australia made no headway in Canberra with either the Government or the Productivity Commission with addressing their major concerns about viability under such extremely trade exposed conditions showed that the situation in their eyes was hopeless.

I believe that if a Labor Government was in power that the views of knowledgeable and reasonable negotiators such as Senator Kim Carr would have prevailed and that realistic strategies to address or counteract all of the concerns of the Australian automotive manufacturers would have been implemented. This would have occurred at the time of Holden’s threatened closure and I believe would have saved the local manufacturing operations of Holden and subsequently also those of Toyota Australia.

Even though during the Rudd and Gillard Governments (as well as the Howard Government) the issues of the vehicle trade imbalance with Thailand, the lack of trade protection in general, the unreasonable barriers placed against exports, the occasional unwillingness to export and the historically high Australian dollar were not adequately addressed, I believe that Labor would have done whatever was needed to retain the Australian automotive manufacturing industry as soon as it became aware of how critical the current situation had become.

Given the above, the only reasonable conclusion that can be drawn is that the current Coalition Government is primarily responsible for the announced cessation of all Australian automotive manufacture.

Can the Coalition bring themselves to adjust the Australian automotive manufacturing national policy environment sufficiently strongly that Toyota, Holden and possibly also Ford can be persuaded to continue local automotive manufacture beyond the announced closure dates? This is not very likely even though it is strongly in the national interest on so many levels, as it would basically entail the partial abandonment of their neo-liberal economic philosophy which they possibly hold as being more important than the national interest. Perhaps it is time for a leadership spill in the Federal Liberal and National Parties?

Can the next Federal Labor Government, which has every opportunity to win in 2016, bring about a policy environment sufficiently realistic and powerful that Toyota, Holden and possibly also Ford can be persuaded to continue local automotive manufacturing? Despite all the gloom I think that is possible. Even if some or all of the original manufacturers choose not to continue with local manufacturing, it is plausible that other players whether local or foreign may take over the current manufacturing facilities, perhaps even with the original manufacturers holding a minority share of the ownership.

We will see.

Like what we do at The AIMN?

You’ll like it even more knowing that your donation will help us to keep up the good fight.

Chuck in a few bucks and see just how far it goes!

Your contribution to help with the running costs of this site will be gratefully accepted.

You can donate through PayPal or credit card via the button below, or donate via bank transfer: BSB: 062500; A/c no: 10495969